Description:

Sustainable Production of Hydrogen through a Hybrid Water-Splitting Loop

This technology offers significant improvements to hydrogen production through a novel loop system that’s produces hydrogen at both the anode and cathode improving. This process makes a hydrogen production a reality through high efficiency and purity.

Background

The hydrogen economy is seen as vital component of a shift to clean energy and is expected to grow rapidly in the coming years as a renewable energy source to meet the needs in fuel cells, internal combustion engines and turbines. To meet both the demands and environmental regulations a move away from using natural gas as the feedstock must be realised. Water electrolysers convert water into hydrogen and thus when integrated with a renewable electricity source gives a route to absolutely zero-emission process.

Technology

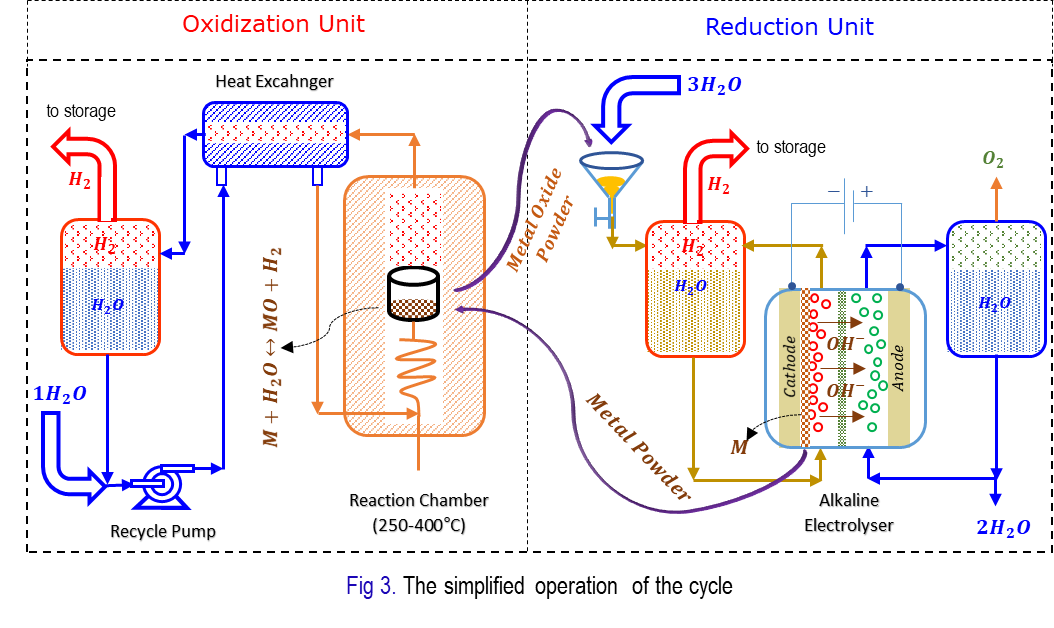

This patented electrolyser technology is current the only catalytic system that produces hydrogen at both reduction and oxidation cycles. The production at both red-ox process’ that must occur, to recycle the catalyst, gives step change increase in hydrogen production for a given energy input compared to other electrolysers on the market.

- Novel continuous process – current systems only produce hydrogen in one reaction direction.

- Red-ox (reduction-oxidation) metal/metal-oxide loop capable of producing hydrogen in both reactions.

- None of the current processes can produce H2 in both reduction/oxidation steps.

- Highly-efficient and highly-pure H2 production

- uses only 2.5 kWh of energy for producing 1kg of hydrogen

- Heat-recovery system further improved efficiency - integrating with the heat recovered from metal hydride formation, if it is used as a preferred process for hydrogen storage

- Improved sustainability by an energy efficiency electrolyser – higher by 2.7 times compared to commercial-available electrolysers due to using a novel ionic-activator

- Environmentally friendly - integrating the process with renewable electricity (wind, solar, hydro-power), it will be an absolutely zero-emission process.

Key Benefits

1. Highly efficient H2 production – open up hydrogen economy

Novel fully cyclic system to produce hydrogen highly efficiently in both the forward and back reactions.

2. Novel ionic activators – reduce operating costs

Improving cell efficiency thereby reducing energy consumed and associated operating costs

3. Fully sustainable integrated system

Exothermic oxidation unit with heat recovery integration further reducing systems energy input, using no fossil fuels

4. Environmentally friendly – meet CO2 targets

Absolutely zero emission, if the reduction unit is integrated with renewable electricity supply, e.g. wind, solar, hydro etc

Contact:

Will Mortimore Technology Transfer Manager

Tel: +44 (0)1483 68 4909 w.mortimore@surrey.ac.uk

Inventor:

Dr Bahman Amini Horri

Academic Founder

Dr Horri is a Lecturer at the Department of Chemical and Process Engineering. His practical engineering background is in the field of oil and gas industry with six years experience in developing innovative processes for natural gas conversion, carbon nano-tubes, and nanocatalysts. His current research interests are: hydrogen production, Solid oxide fuel cells and nanomaterial synthesis.

Professor Sai Gu

Academic Founder

Prof Gu is Head of the Department of Chemical and Process Engineering, Professor of Chemical Engineering. He has an international reputation for clean energy and material research, focused on the development of advanced bio-energy and carbon capture technologies. He has successfully won over £10 million in grants from EPSRC, EU, Innovate UK and industry.