Description:

Novel Conductive Inks

A patent-pending novel high concentration Nickel Oxide (NiO) ink compositions with excellent jetting and storage properties, for a number of applications including printable supercapacitors.

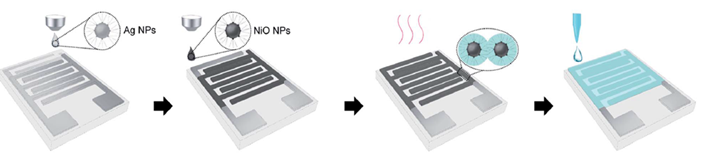

Figure: Schematic of inkjet printed NiO micro-supercapacitors

NiO is very promising semiconducting material, especially in its nanoparticle form, for electronic and opto-electronics devices, with very broad range of applications in energy generation and storage, sensors, light emitting diodes, memory. However, there is no commercially available inkjet printable NiO inks available on the market.

University of Surrey academics Maxim Shkunov and Pavlos Giannakou, have developed NiO ink formulations. The NiO nanoparticle is combined with base solvents for the production of high concentrated nanoparticles which are well distributed. Base solvents in the composition have low surface tension allowing for good adhesion between the printed layer and the substrate, good jetting performance of the ink and compatibility with numerous commercial and industrial inkjet printers.

The ink demonstrates highly stable droplet formation and ejection with no nozzle clogging and satellite droplet formation. In addition, the ink shows very stable properties, with shelf life of up to 18 months with no signs of particle agglomeration or solvent evaporation.

Multiple layers can be successfully printed without the subsequent layer breaking the boundaries of the preceding layers that can lead to distorted pattern dimensions.

The nanoparticle ink composition can be easily adjusted to be compatible with a large range of ink formats including; inkjet printing, aerosol jet printing, screen-printing, spray-coating, doctor blading, spin-coating, roll-to-roll coating and stamping.

- Traditional ink jet printing

- Printable electronics, ideal for autonomous wireless sensors, internet-of-things (IoT) and wearable electronics

- Excellent jetting performance

- Low sintering parameters

- Compatible with a wide range of number of printing formats

- Highly stable with a long shelf life